PRESSURE VESSEL, ENGINEERING & FABRICATION

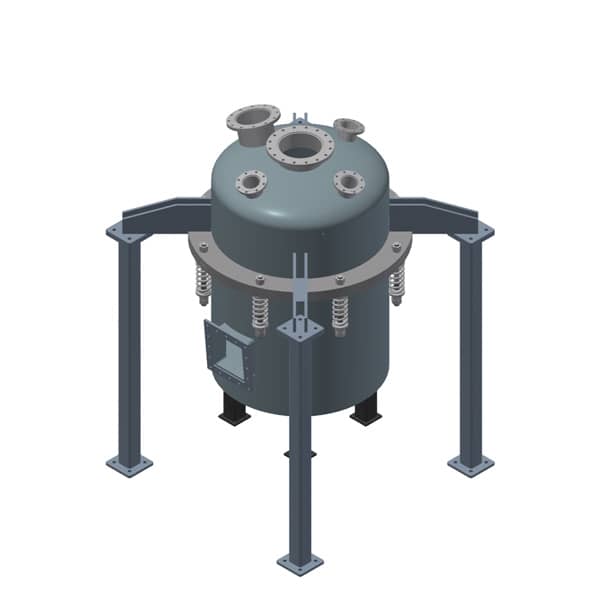

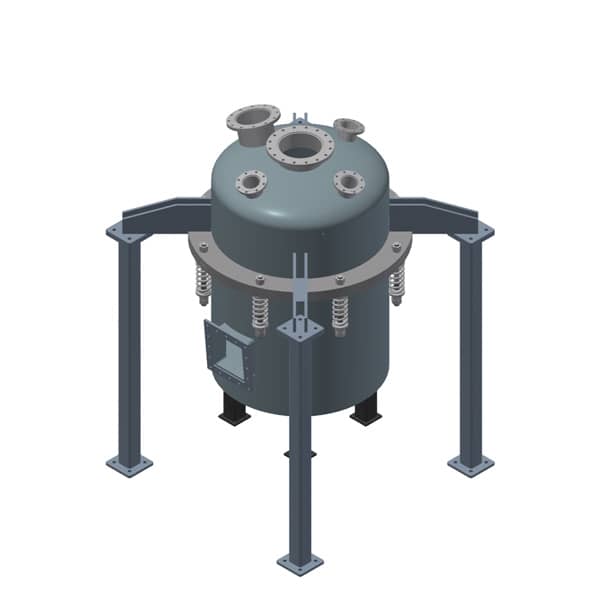

ASME Reactor Furnace

Client

PyroGenesis Canada

Industry

Advanced materials research

Equipment

Reactor Furnace

Materials

Steel

Our Service

Engineering & Fabrication

01

OVERVIEW

A complete vessel design per ASME standards

Looking to further their study into a proprietary advanced material refining process, the client required the expertise of an ASME vessel fabricator for consultation, design, and manufacturing of a steel fabricated vertical Reactor Furnace.

DIMARTECH met with their mechanical engineers to understand their concerns associated with this new process and furnace, which begins with the gas lance surpassing 2000 F. The addition of an internal protective refractory coating is necessary to ensure the furnace’s life span. The vertical furnace body is to be split in half with welded girth body flanges.

Client

PyroGenesis Canada

Industry

Advanced materials research

Equipment

Reactor Furnace

Materials

Steel

Our Service

Engineering & Fabrication

02

APPROACH

Complete design and manufacture per ASME standards

DIMARTECH provided a complete vessel design per ASME standards, and proposed three variations for the non-standard bolted flange assembly, taking into consideration the heat transfer flows, sealing integrity, stress concentration factors and vacuum resistance in case of upset process conditions.

Various bolting patterns were proposed with using different o-ring sealing materials: silicon, copper, and graphite. The o-rings were analyzed on different bolt circles to attempt to use the most appropriate model but at a sufficient distance to prevent overheating and failure.

The bottom of the crucible was designed and modelized with Codeware Compress software with particular attention given to reducing any possible stress concentrations discontinuity factors at the bottom corners.

03

DELIVERY

ASME vessel fabricator for consultation, design and manufacturing of a steel fabricated vertical Reactor Furnace

With a positive and engaging collaboration, the design was finalized and agreed to before putting into fabrication. Manufacturing was completed per the newly created specifications, and the furnace was successfully delivered to the end user’s facility for further research. At the time of this writing, they have advised us that they are in the final stages of their data collection before initiating commercialization of their process, and we are proud to have been part of their success.

GET A FIRM ESTIMATE FOR YOUR PROJECT

Pre-Fabrication Analysis Plan